iAqua Stingray ONE

Each component on iAqua Stingray ONE has been carefully engineered to deliver maximum bang for your buck. In doing so, we have created a craft that belies its modest price-tag with some eyebrow raising stats. Whilst this is our ‘entry-level’ version, be prepared to be thrilled; surging through the water at 14km/h and diving to a depth of 20m Stingray ONE is the perfect introduction to what is possible at iAQUA.

- 16 km/h max speed

- 20 m maximum depth

- 3.3 kW max power output

- 650 N max propulsive force

- 5 power modes

- Run time 70 mins

- Fast-charge 120 mins (standard trickle-charge 7hrs)

- Weight 37kg

- Dimensions L108cm, W50cm, H40cm

Choose your iAqua Stingray ONE

ONE finishes

Stingray ONE bodywork is made from high-impact PC-ABS. It goes through the same automotive painting process as NEO, but in order to keep unnecessary cost to a minimum is only available in solid colours. Selected to match ONE’s hull and trim parts, you can’t go wrong with the monochromatic solid colour options of Arctic White, Baltic Gray and Hadal Black (named after the deepest regions of our oceans).

iAQUA DESIGN

In manufacturing iAQUA products, we wanted to use the same processes, techniques and software that we have perfected for our automotive components. Duo (our Lead Designer) started sketching initial ideas for a sea scooter, after a few weeks of styling and packaging design in CAD, Stingray was conceptualised in a full-size physical 3D clay. The highly skilled process of carving a clay is usually the realm of automotive design studios, but we wanted to ensure the form and lines were perfect.

The clay surfaces were digitized using a 3D laser scanner with any imperfections solved in a-class surfacing software. Vital design considerations such as the hydrodynamics, buoyancy and ergonomics were manipulated in solid-3D modelling software before committing the parts into tooling.

Unlike smaller design firms we have large-scale tooling facilities available in-house, so were able to tune the design and parts in real time. In developing our own tools we could many solve the technical, performance and manufacturing challenges whilst ensuring the final bodywork and hull was as Duo originally conceived.

ENGINEERING & DEVELOPMENT

Having cut our teeth supplying some of the most demanding automotive companies in the world, we have adopted the same stringent manufacturing and testing practices at iAQUA. Each of the components within Stingray have been tested far beyond normal operating ranges. Cycling through extreme temperature and pressure cycles and subjected to simulated depths and salinity to ensure our components are always well within their comfort zones, whenever you are on the edge of yours.

By setting our standards high we have created ourselves a huge engineering challenge. As with all the components, we tested the Electric Control Module (the nerve centre of Stingray) to a simulated depth of 40m for an hour – the pressure at that depth is 73 psi, or the equivalent of parking a medium size car on a small lunch-box.

Each Stingray is built to order in our factory in Shenzhen – all the components are tested individually before going into the assembly and Stingray is tested physically and diagnostically before leaving the factory.

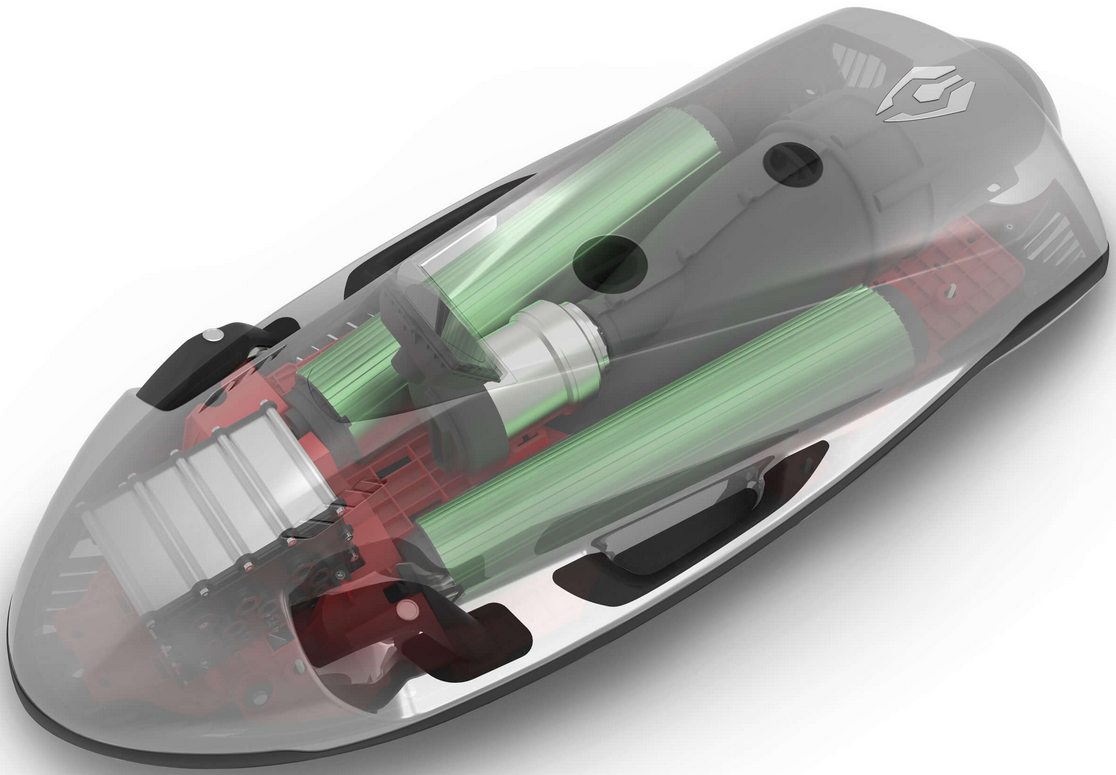

BATTERY TECHNOLOGY

The twin battery packs are not just the heaviest components within iAQUA products, they are also the most critical for performance; power output, longevity and recharge time are all determined by the cell design. Rather than taking on a proprietary system, we developed our own; from the bright green anodised casing to the battery management software, it has been optimised for iAQUA and developed with the leading cell manufacturers in the world.

Within each of the aluminium canisters are 96 individual Lithium Ion cells, providing each battery with a nominal voltage of 48V. Critical to the battery design is the management hardware and software which controls the discharge and recharge of the cells and ensures they operate within normal conditions, providing the motors with a consistent supply of power.

The anodised aluminium alloy canisters have been pressure tested to 40m and subjected to extremes of temperature and salinity to ensure that they provide reliable power for the waterjets in any conditions.

However, as with any rechargeable device the batteries have a finite number of discharge/recharge cycles before they begin to lose their charge – bad charging habits and extreme temperatures will further decrease the life. So we have made the battery units easily replaceable; using basic tools following the online videos you can replace the batteries within a few minutes.

MODULAR DESIGN

Keeping things simple takes a lot of effort. Anyone who has attempted to fix a broken gadget will agree, they are rarely designed to be repaired and even the act of taking them apart can render them completely unusable. Stingray has been designed so that with basic set of tools and instructions the main components can easily be serviced or replaced.

Stingray is effectively built from four main mouldings; hull, water inlet, chassis and bodywork with five internal plug-and-play components; batteries, electronic control module, control grips, display and propulsion unit. Each of the components are pressure sealed and designed to be easily replaced by way of waterproof electrical connections and stainless steel fixings.

If a component becomes worn or breaks, rather than sending Stingray back to the factory you can order replacement parts from our website and they will be sent to you. There are a set of instructional videos on our site that guide you step by step how to replace the components and to ensure correct installation and water resistance.

Contact us for further details!

*Please use the iAqua to your abilities, diving requires specific training and you should consult a professional if this is how you would like to enjoy your purchase.

| Weight | 41 kg |

|---|---|

| Dimensions | 115 × 55 × 45 cm |

| Maximum Speed | Up to 16 km/h |

| Maximum Depth | 20m |

| Maximum Power | 3300w |

| Battery | 400Wh, 15Ah Lithium Battery |

| Operating Time | 70 Mins |

| Charging Time | 7 hours (standard), 2 hours (fast) |

| Cruising Range | 6km |

| Size (LxWxH) | 108 x 50 x 40cm |

| Weight | 37kg |

| Colours | Arctic White, Baltic Grey, Hadal Black |

| Speeds | 5x Power Modes |

1 Year Manufacturers Warranty

Reviews