After Fifty Years, What’s Still so Great about AGM?

ARTICLE CREDIT: AARON PLEW, PRODUCT DIRECTOR AT FULLRIVER BATTERY USA

AVAILABLE THROUGHOUT ASIA FROM DRAKE MARINE

DRAKE MARINE / RESOURCES / CASE STUDIES / AFTER FIFTY YEARS WHAT’S STILL SO GREAT ABOUT AGM

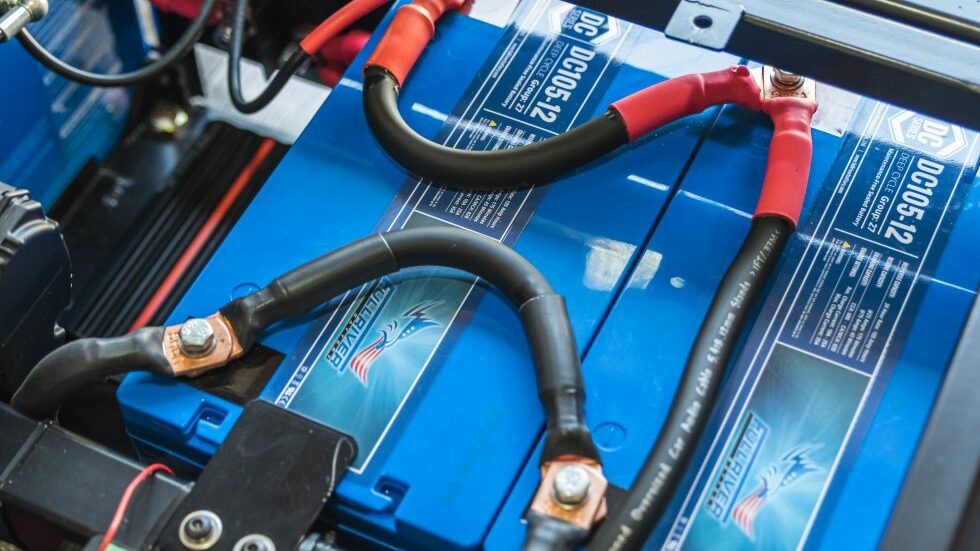

AGM batteries have been on the market for right around 50 years, preceded by gel batteries by almost 40 years. With all the excitement surrounding newer technologies in energy storage, it’s time to take a step back and consider some of the great things this half-century old technology still has going for it. The usual caveat applies, this article will focus on what we know, high-quality Fullriver AGM batteries.

Zero-Maintenance

Part of the original appeal of AGM, remains a giant consideration today, zero-maintenance. In a commercial setting, maintenance means down-time, and down-time means lost revenue. Maintaining a conventional battery also means special equipment for watering, replacing lugs and cable segments due to corrosion, and timing all of this around charging cycles. Who will maintain the battery, and who will train the battery maintainer, and who will maintain the schedule of battery maintenance? When maintenance is neglected, the results are failed batteries, equipment downtime, and replacement costs.

For rental fleets, remote applications, or hot environments that necessitate frequent watering, maintenance-free AGM is the obvious choice, but even a warehouse setting, airport, and especially on large campus, maintenance demands can quickly become overwhelming.

Safety

This leads us to our next consideration, safety. Of course, with conventional batteries, free-flowing sulfuric acid and hydrogen gas emissions both present opportunities for disaster. In today’s workplaces, there’s no room for accidents because the stakes and implications are not good. “But” you say, “We replaced our flooded batteries with lithium!” Here we will not delve into fear-mongering polemics, but only note that even among the “safest” chemistries of lithium, it is undisputed that thermal runaway is still far more likely than in an AGM battery. While all batteries carry with them inherent dangers, a case could easily be made that a brand like Fullriver AGM are the safest form of deep-cycle battery available.

While sensitive environments like hospitals and museums already demand AGM batteries, food processing facilities also find it advantageous. But what industry doesn’t need a high-level of safety from its equipment?

Cost

Of course, the most widely used battery type in commercial and industrial applications is still the conventional/flooded cell battery. Flooded batteries boast an attractive price point up front. Next in line for initial cost after flooded is of course AGM, and then comes lithium with the highest price point by far.

Admittedly, for small fleets working in a manageable footprint, the maintenance of a flooded battery could easily be managed if the budget calls for it. And, if the workforce isn’t limited by a busy workload, of course. As the scale of the operation shifts or the footprint of the worksite increases (e.g., hard to get to all the vehicles for maintenance) then the upfront savings of flooded can quickly dry up (wink).

Lithium to the rescue, right? It’s low maintenance, so no worries there, but the cost is a real issue for many corporate bottom lines that typically want to realize ROI in 3 years, not the 4-5 that it typically takes lithium.

Every business will have their own priorities, and existing infrastructures to support them. Fullriver AGM’s upfront cost is typically supported by a longer warranty, and a much higher cyclic capability compared to conventional. While AGM doesn’t claim as many cycles as lithium, the analog nature of AGM (i.e., no internal electronics to fail) ensures it will be much more likely to attain its published cycle life in the real world.

Availability

Reality can be unforgiving, and that means things will go sideways without notice. People make mistakes, things get broken, or they break themselves. When this happens, as it inevitably will, how easy will it be to replace quickly? Thanks to several factors, you can find conventional and AGM batteries within spitting distance of most businesses in all but the most rural of locales. With lead-acid batteries aplenty, you could be down in the morning and up by the afternoon. With newer battery technologies in commercial applications, you could be down for weeks waiting for a replacement, and because lithium is shipped under Class 9, Dangerous Goods, forget about air freight.

End of Life

A very good question customers should ask their sales reps is, “What happens when the battery needs to be replaced?” If it’s a lead-acid battery (i.e., flooded, agm, gel) then not only is the entire battery going to be recycled, but it’s likely to be of significant value. It never takes very long to get these types of batteries picked up and a check in hand for their exchange. Lithium is nowhere near this easy type of exchange. In some cases, you may even have to pay to have it removed and disposed of. Wow, thanks. Sadly, if the company that sold it to you does pick it up for free, it will likely sit in their warehouse until they pay for its disposal. Lithium advocates will note that this will change, but many have tried, and none yet succeeded.

ICE Vehicle Fleets

Servicing the battery needs of fleets of work trucks, emergency service vehicles, rapid transit buses and vans, is a monumental task. In addition to all the maintenance that flooded batteries require (e.g., periodic boost charging), other challenges exist in these environments. When it comes to climate versality, AGM outstrips everything else. TPPL batteries especially like Full Throttle aren’t impacted by hot-start issues. In the cold of winter, firing up a bus has often been a thorn in the side of conventional batteries. Then there are the accessories that modern vehicles must support that the old sponge lead battery just can’t keep up with, not for long anyway.

At this point, lithium has had little impact in this space, mostly due to the specialization required to design a battery for these applications. The lithium that has been produced for mixed-use (starting and cycling) has either underperformed or been too costly to justify. In the end, the cost of lithium for these applications just doesn’t add up compared to the all-around performance capability of AGM.

50 Years and Counting

As AGM achieves a half century of usage, and familiarity with the technology grows, there is almost no application that it is not used in. Whatever the application may be, safety, reliability, cost of ownership, and ease of recycling and replacement are the biggest factors that continue to contribute to the popularity of high-quality AGM products like Fullriver has been making for 25 of those 50 years.

And that, in our experience, is what make a true deep-cycle battery. Attention to design details, rigorous manufacturing standards, and the best components. It’s not any one thing by itself, but the sum of its parts that makes it great.

ARTICLE CREDIT: AARON PLEW, PRODUCT DIRECTOR AT FULLRIVER BATTERY USA

AVAILABLE THROUGHOUT ASIA FROM DRAKE MARINE